Wishing you joy and happiness this holiday season!

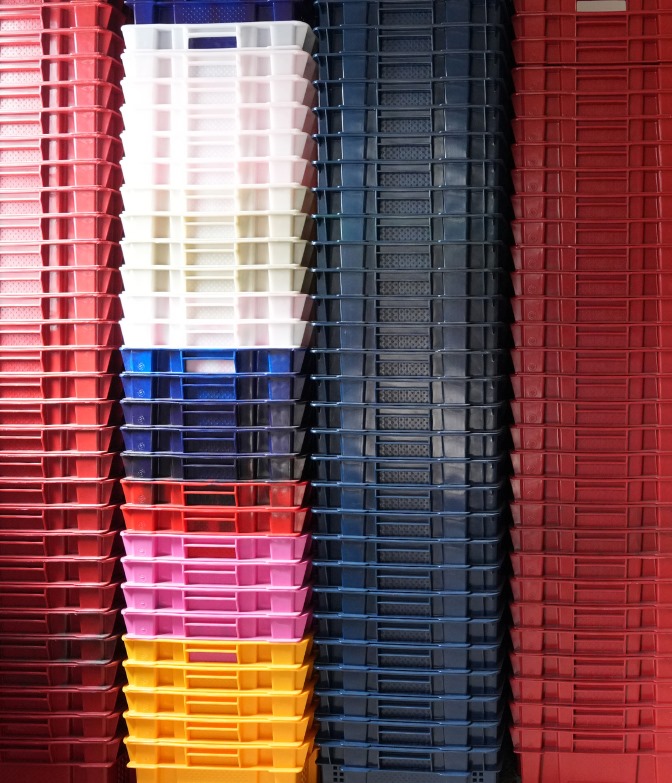

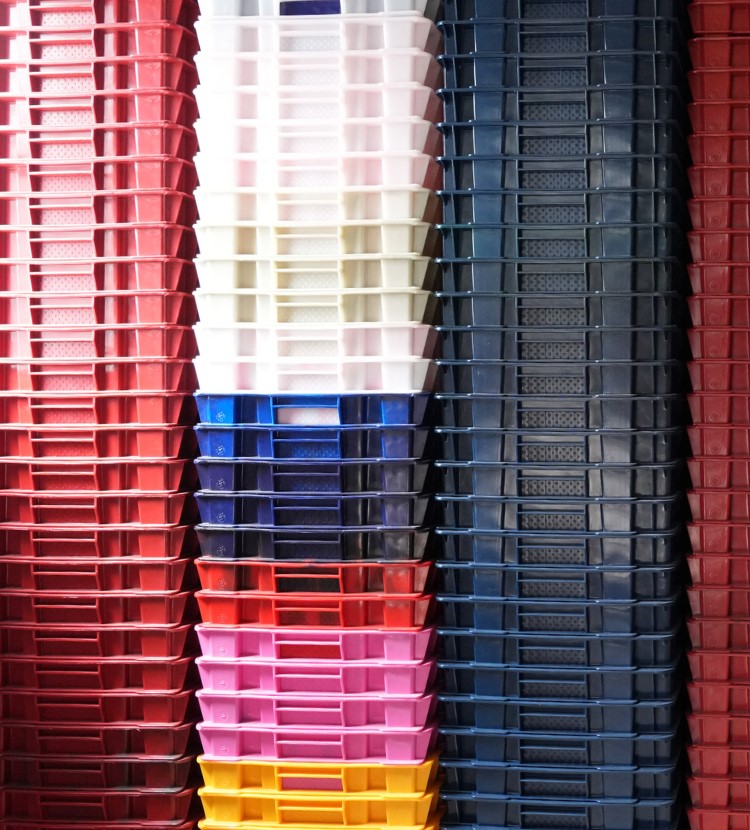

Founded in 2006, Pro Plast s.a.r.l. is a leading manufacturer of high-quality plastic crates in Lebanon, proudly serving a wide range of sectors within the food industry, agriculture, bakery, meat, and more.

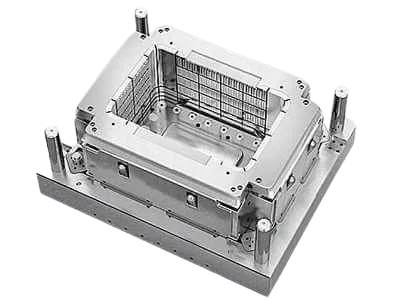

Our strong affiliation with Plastic Consulting Engineering (P.C.E.), our sister company established in 1990, positions us at the forefront of plastic injection mold production and maintenance. Furthermore, our strategic partnership with GamaPlast-Bulgaria significantly enhances our technological edge, allowing us to meet and exceed our customers’ expectations.

P.C.E. hosts a mechanical workshop that utilizes advanced Computer Numerical Control (CNC) technology. We use the latest 3D CAD/CAM software to design molds, guaranteeing our clients receive top-quality in-house injection molds.

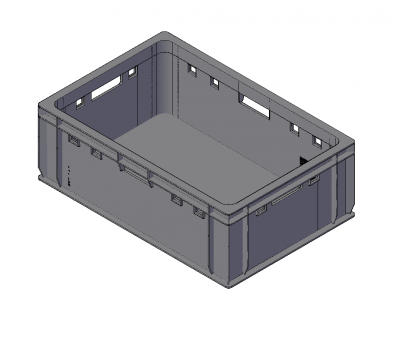

The process begins with the design of the part, followed by the creation of a prototype. CAD (Computer-Aided Design) software is often utilized to ensure precision and accuracy.

A mold is fabricated, typically from steel or aluminum, which consists of two halves: the cavity and the core. This mold is designed to withstand high pressure and temperature. Then Plastic pellets or granules are heated until they melt and are then injected into the mold under high pressure. This ensures that the molten plastic fills every part of the mold completely.

The injected plastic cools and solidifies within the mold, taking the shape of the desired part. Cooling time can vary depending on the material and thickness of the part. Then Once the plastic has cooled, the mold opens, and the finished part is ejected. This step may involve the use of ejector pins or plates to assist in removing the part without damage.

The final step may include trimming, painting, or additional finishing processes to meet specific requirements.